Engine & Tune-up

Listen, repeat, memorize!

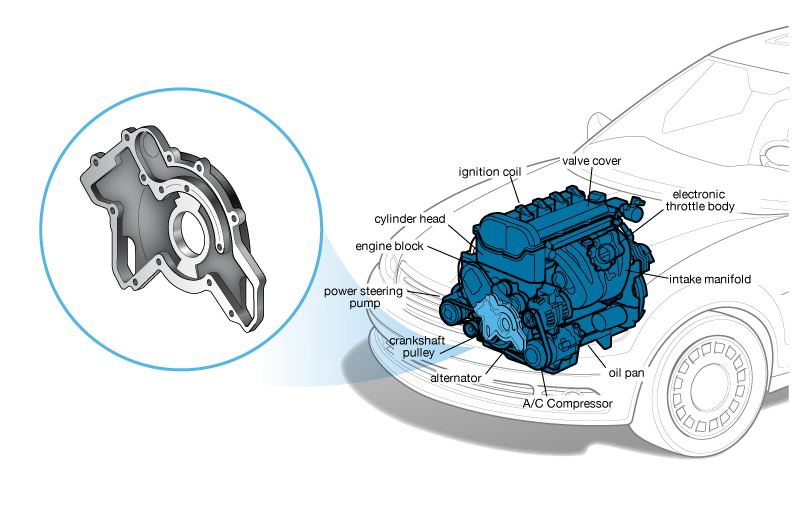

Oil Pump

An engine needs oil to lubricate moving parts, prevent corrosion, collect dirt and sludge, and absorb some of the heat generated by a running engine.

The oil pump provides the force that delivers oil through galleries and passages around the engine.

Oil pumps are usually either inside the oil pan and driven by a camshaft or outside the pan and driven by a crankshaft.

When those engine parts start moving, the pump starts working at the same time to pump oil to reduce friction and wear between moving parts and prevent the engine from seizing.

If an oil pump stops working, or there is little or no oil because of leaks, engine parts can overheat in a matter of seconds and seize from a lack of lubrication.

Checking or replacing an oil pump is not part of routine service or maintenance, but because it’s critical to an engine any warning signs should be addressed immediately.

When a warning light comes on, the best approach is to shut the engine off, wait several minutes and check the oil level.

If the oil level is normal and the warning light comes on again when the engine is restarted, continuing to run the engine increases the risk of major damage.- Listen to the Text:

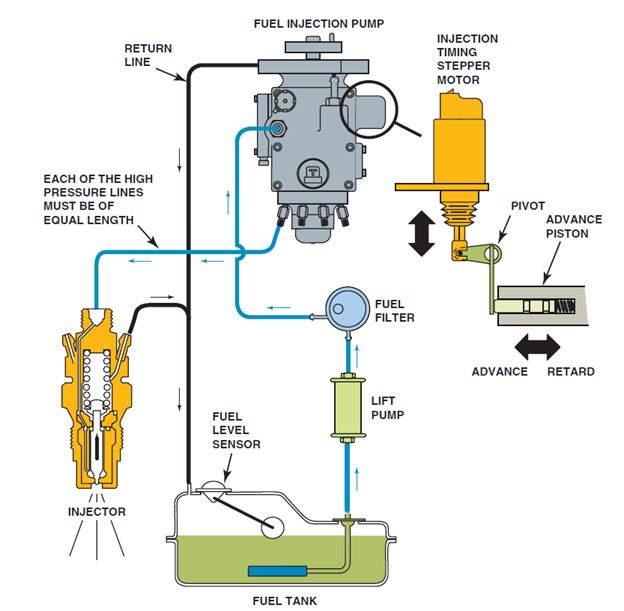

Diesel Injection Pump

Listen, repeat, memorize!

Diesel engines operate at higher compression ratios than gasoline engines, and fuel is injected under much higher pressure.

An injection pump, usually driven by a belt or chain linked to the crankshaft, does this by supplying fuel under high pressure (15,000 pounds per square inch or more) to the injectors for each cylinder.

As with gasoline engines, diesel injection pumps are controlled by the engine control module in order to deliver the correct amount of fuel at the right time for each cylinder.

With diesel engines, fuel is injected directly into the cylinder, while in most gas engines it’s injected into an intake port (though there are a growing number of gas engines with direct injection).

Diesel engine pumps can be damaged by sludge and other deposits, they can develop leaks and electrical parts can fail.

A worn injection pump will make a diesel engine harder to start and is often accompanied by a loss of power, though a faulty fuel supply pump or dirty fuel filters could also be the cause.

They are usually expensive to replace, ranging up to a few thousand dollars.

That’s why many diesel owners buy remanufactured pumps or have their original pump rebuilt.

Listen to the Text:- Vacuum Leak

Listen, repeat, memorize!

The pumping of an engine’s pistons creates a vacuum in the cylinders, and that vacuum is filled by air drawn in through the intake system.

If leaks develop in hoses or engine parts downstream from the air intake, that means additional air is going into the engine that’s not being “read” by the engine computer, which determines how much fuel to inject into the cylinders based on the amount of air coming in.

The result is an incorrect air-fuel mixture than can create a number of problems, such as hard starting, a rough idle, hesitation, misfiring or a drop in fuel economy – issues that could, without proper diagnosis, seem to have other causes, such as incorrect ignition timing or fouled spark plugs.

A vacuum leak can trigger a “check engine” light because the fuel system is running too “lean,” meaning it has a greater mix of air than is ideal.

Vacuum leaks can develop in many locations, including the intake manifold, throttle body evaporative emissions system, power brake booster, and several other places, because some vehicles have a multitude of vacuum hoses.

The problems that arise from an engine vacuum leak can be more than annoying.

Idle speed that is way too fast is one of the difficulties, and stalling is another.

Confirmation of an engine vacuum leak can be a very loud hissing sound coming from the engine area.

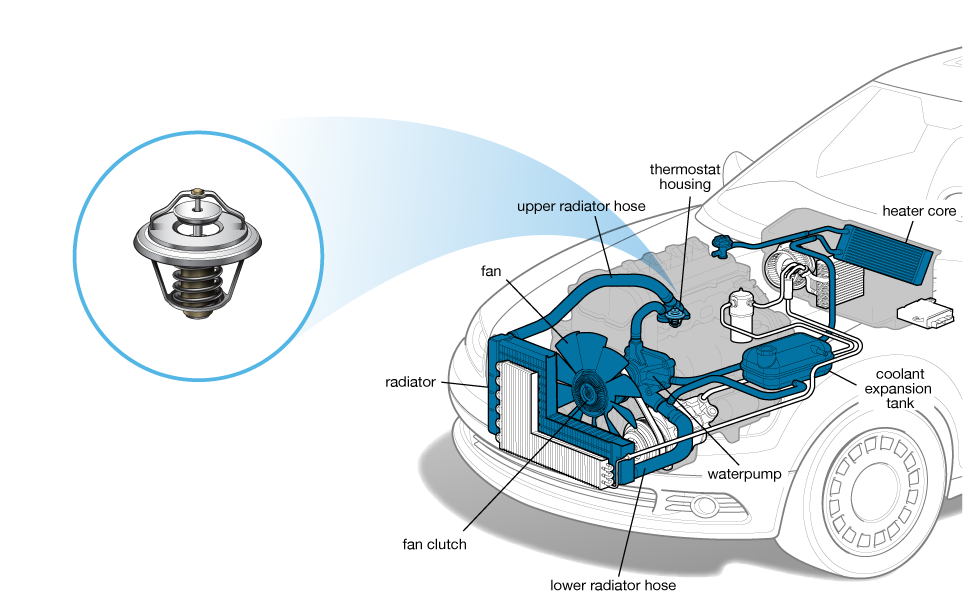

Listen to the Text:- Thermostat

Listen, repeat, memorize!

The thermostat cuts off the flow of coolant to the radiator when the engine is cold so that heat generated by the engine warms the coolant.

Once the coolant warms to a specific level, a valve in the thermostat is supposed to open so that coolant flows through the radiator to cool off before being pumped back through the engine in a continuous cycle.

If a thermostat is open all the time, the coolant will constantly be circulating through the radiator and the engine will take longer to warm up as a result.

If a thermostat is stuck in the closed position, the engine could overheat because coolant isn’t circulating through the radiator and shedding some heat.

In either case, the thermostat should be replaced.

Even if the thermostat opens and closes when it’s supposed to, the housing gasket could develop a leak and need replacing.

The thermostat is typically located where the upper radiator hose enters the engine.

Thermostat replacement usually isn’t listed in vehicle maintenance schedules, and some mechanics advise that as long as it’s working there’s no need to replace it.

On the other hand, if the coolant is being flushed at, say, 100,000 miles, or radiator hoses are being replaced, many repair shops will suggest replacing the thermostat at the same time.

Listen to the Text: