Engine & Tune-up (Part 2)

Listen, repeat, memorize!

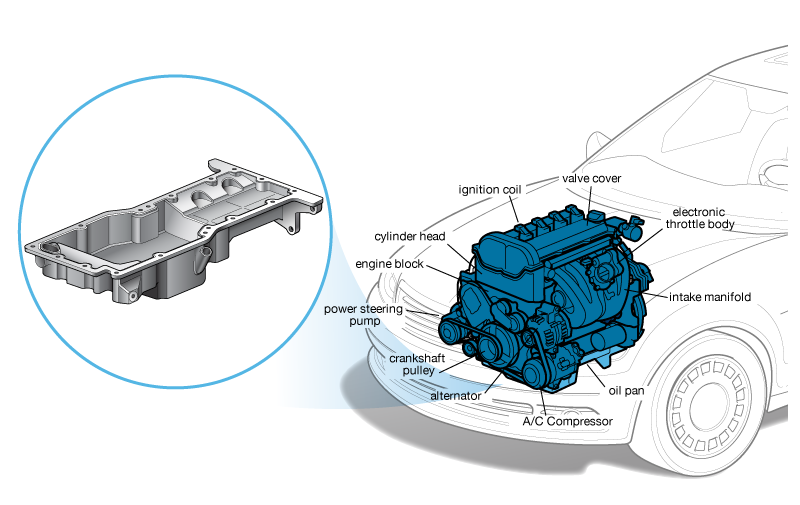

Oil Pan

The oil pan is attached to the bottom of the engine with bolts and is the reservoir for oil that gets pumped throughout the engine to lubricate, clean and cool moving parts.

A pump forces the oil from the pan through a filter to remove dirt and other debris before it circulates through the engine.

The pan is usually made of steel or aluminum and typically holds from four to six quarts of oil, depending on the engine.

The oil dipstick extends into the oil pan and measures the oil level in the reservoir.

A drain plug on the bottom can be removed to drain oil.

Oil leaks are common on engines as they accumulate miles, and oil pans can be one source of leaks or seepage.

Gaskets or seals installed where the pan attaches to the engine block may wear out and allow leaks.

Drain plugs can leak if they are over-tightened or, in some cases, if washers aren’t replaced when the oil is changed.

Pans also can be damaged when a vehicle goes off-road (whether intentionally or by accident) and hits a rock or other hard object.- Listen to the Text:

Wheels, Steering & Suspension

Listen, repeat, memorize!

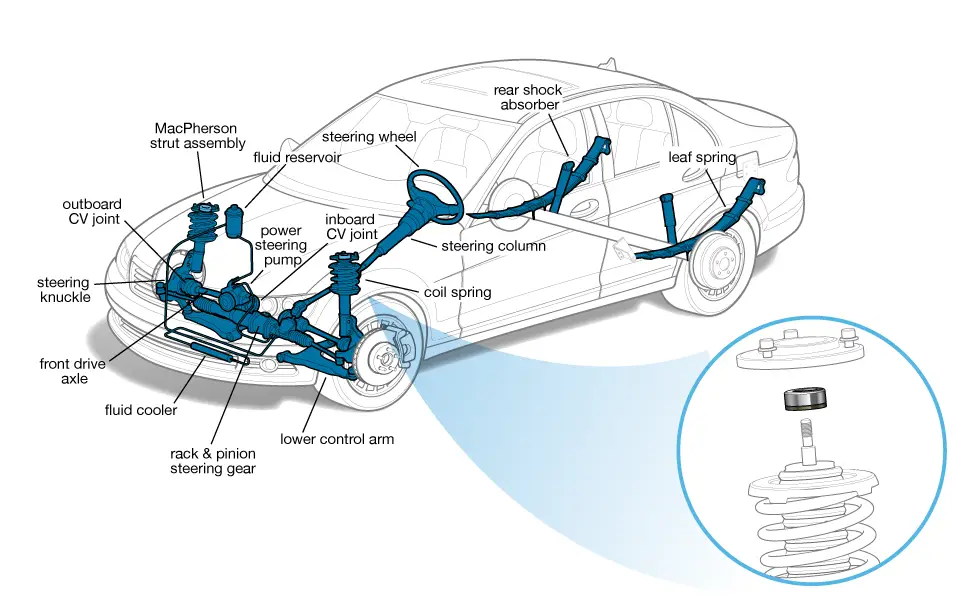

Strut Bearing

On many vehicles with strut-type suspension designs, the front struts (which include the springs and shock absorbers) are mounted with bearings or bearing plates that serve as the upper pivot points for the steering.

The bearings can wear out from long-term use, corrosion, impact or collision damage, and other factors.

When they do, they often make knocking or clunking noises over bumps or in turns, or the steering becomes stiff or snaps back toward center when the driver lets go of the steering wheel.

Bad strut bearings can also cause alignment issues and uneven tire wear.

Many mechanics recommend that strut bearings be replaced whenever struts are replaced so worn bearings don’t affect suspension or steering performance.

Some replacement parts come as a complete assembly with struts, springs, bearing plates and mounting hardware.

In addition, strut assemblies should be replaced in pairs, not just one side at a time, and the vehicle should also get a wheel alignment after the struts and/or bearing plates are replaced.

One advantage of buying a complete strut assembly instead of individual parts is that with the complete kit, removing and installing the strut assembly doesn’t require a spring compressor, a tool that can cause serious injury when not used properly.

Listen to the Text:- Steering Gearbox

Listen, repeat, memorize!

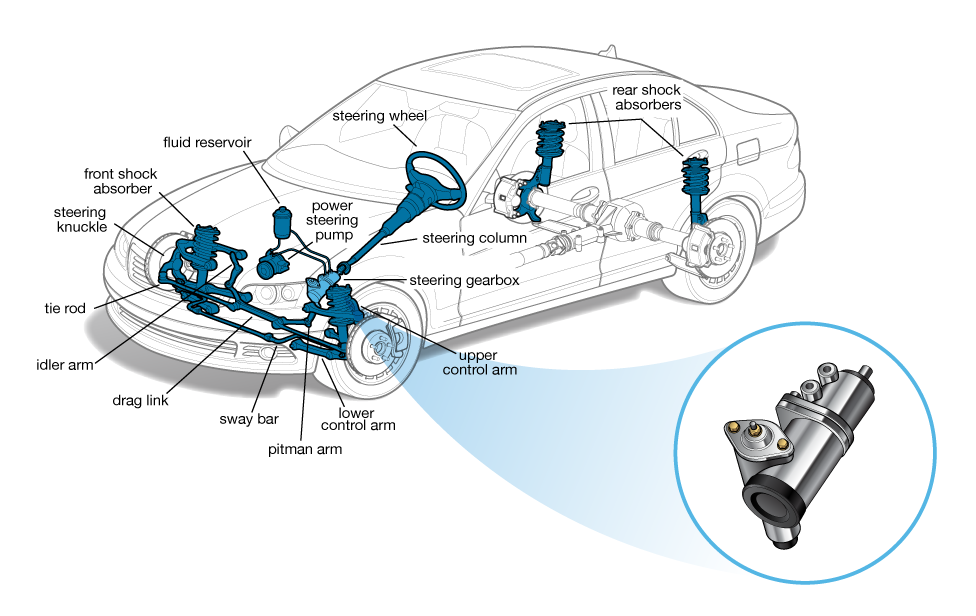

The steering gearbox contains the gears that transmit the driver’s steering inputs to the steering linkage that turns the wheels, and it multiplies the driver’s steering changes so that the front wheels move more than the steering wheel.

Most car-based vehicles use rack-and-pinion steering in which the steering wheel turns a pinion gear that moves on a rack to turn the front wheels.

Others use recirculating ball systems in which ball bearings are mounted on a “worm”-type steering gear.

Though steering gears often last for the life of a vehicle, the gearbox can develop leaks or the gearbox case can crack.

Among the signs that a steering gearbox needs repair or replacement are increased or jerky steering effort, and the steering becoming loose and showing excessive play.

Listen to the Text:- Ball Joint

Listen, repeat, memorize!

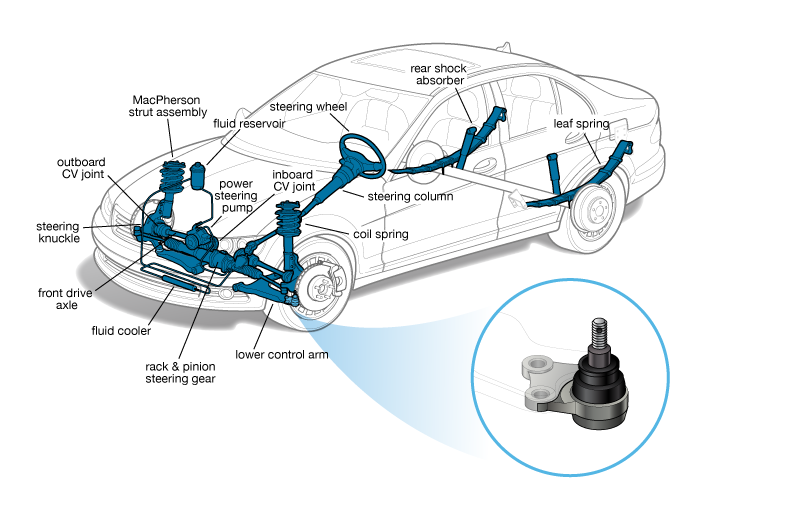

Ball joints act like hinges and connect the suspension control arms to the steering knuckles with a rotating, spherical stud and a socket, giving the wheels a wide range of movement – from side to side for steering and up and down for going over bumps.

Some vehicles have upper and lower front ball joints, and depending on the suspension design either can be the load-bearing joint that carries the vehicle’s weight (load-bearing joints tend to wear out sooner).

Vehicles with McPherson strut suspensions have only lower ball joints, and some vehicles also have rear ball joints.

Most vehicles come with sealed ball joints that don’t need periodic lubrication (“greasing” them used to be a routine part of oil changes), but the internal lubrication or seals can wear out over time.

When ball joints wear, they allow too much suspension movement, resulting in shimmies or shakes on smooth roads, steering that wanders from straight ahead, or uneven tire wear.

They may give audible warnings that they need to be replaced by squeaking or clunking, especially over bumps or when turning.

Some ball joints have wear indicators, but mechanics can also determine if they’re worn by jacking up the vehicle and seeing if there’s excessive play by rocking the wheel back and forth.

Listen to the Text: