Brakes

Listen, repeat, memorize!

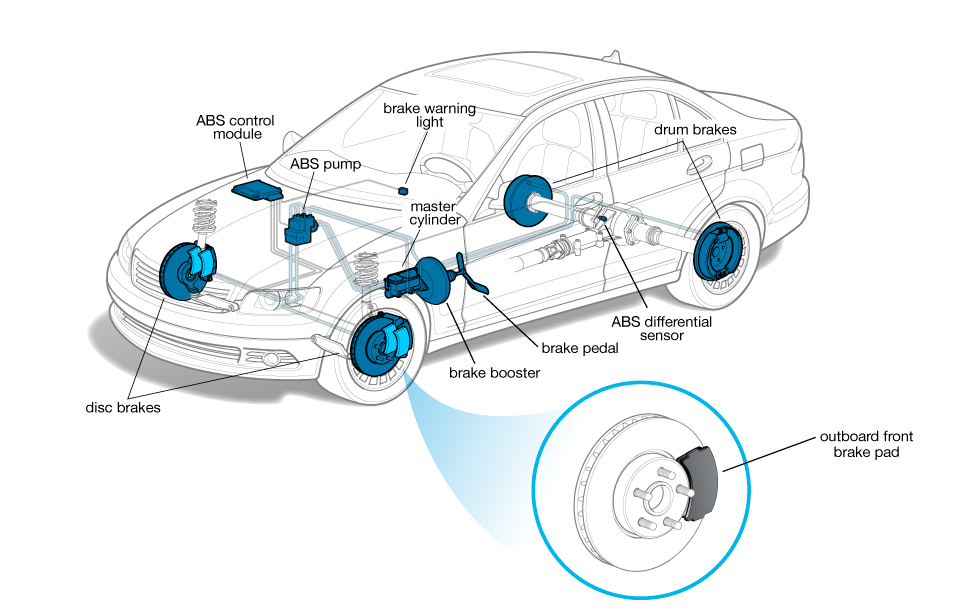

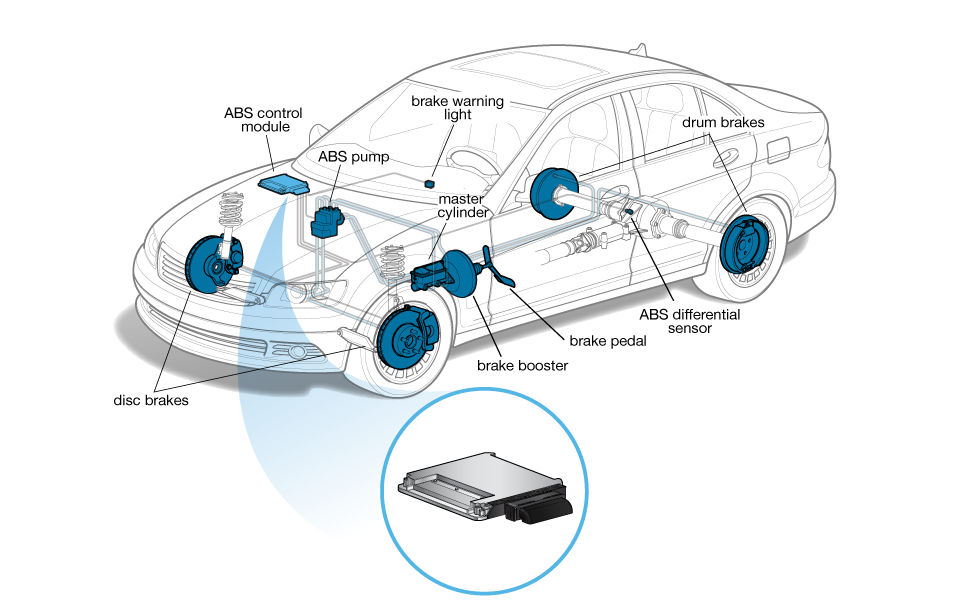

Antilock braking system (ABS)

Antilock braking system is an enhanced braking system that monitors individual wheel rotation and prevents the wheels from locking up while stopping.

Locked wheels provide inefficient braking and sacrifice directional control, so ABS shortens stopping distances in most conditions and allows the driver to steer even when panic braking.

The federal government began requiring ABS on all new cars starting with the 2012 model year.

Pulsation in the brake pedal can startle the uninitiated, but it is a sign of the ABS properly doing its job.

In structure, ABS is similar to a conventional braking system, but its components may need repair, starting with electronic wheel sensors at each wheel or at the differential, the computer brain called the control module, and a valve assembly and pump.

Stopping a car in a hurry on a slippery road can be very challenging.

Anti-lock braking systems (ABS) take a lot of the challenge out of this sometimes nerve-wracking event.- Listen to the Text:

Brake Booster

Listen, repeat, memorize!

In power brake systems, which are found on virtually all vehicles, the brake booster is a component that multiplies the force the driver applies to the brake pedal.

A brake booster is to braking what power steering is to steering.

A brake booster uses a stored vacuum to overcome the high fluid pressure in a car’s braking system.

With a brake booster, the driver does not have to exert much force on the brake pedal when applying the brakes.

If the booster fails, excessive pedal force will be required to achieve adequate braking.

Most brake boosters run on a vacuum produced by the engine.

The cause of booster failure can be as simple as a loose vacuum hose or a ruptured diaphragm that requires component replacement..

Listen to the Text:- Brake Master Cylinder

Listen, repeat, memorize!

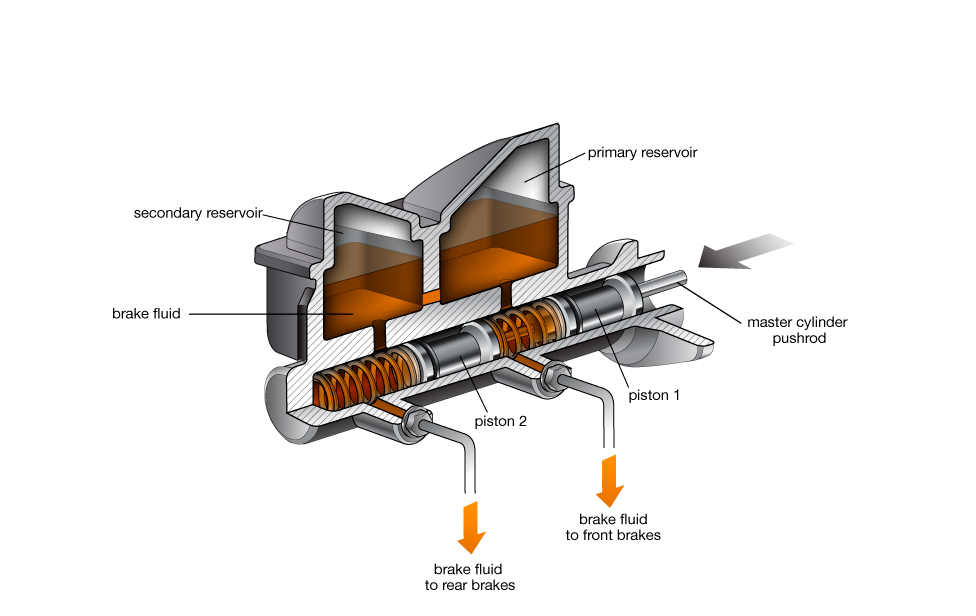

The master cylinder converts the mechanical force from the brake pedal into hydraulic pressure.

When the brake pedal is depressed, the master cylinder piston moves forward and pushes the brake fluid ahead of it.

Over time, with constant use, the seals inside of the cylinder can wear out and form internal leaks.

A bad brake master cylinder may result in a pedal that feels mushy, spongy, or that slowly sinks to the floor when depressed.

The brake master cylinder is the first component in a vehicle’s braking system, activated by depressing the brake pedal.

The pedal pushes a piston through this cylinder, forcing brake fluid through brake lines to slave cylinders at each wheel, which in turn drive the pistons that force friction material against the wheel hubs, stopping the wheel.

The master cylinder is designed to last the life of the car, but like brake calipers, sometimes it can spring leaks or otherwise fail, and it must be rebuilt or replaced.

The cause of booster failure can be as simple as a loose vacuum hose or a ruptured diaphragm that requires component replacement.

Listen to the Text:- Brake Shoe and Drum

Listen, repeat, memorize!

A drum brake is a brake that uses friction caused by a set of shoes or pads that press outward against a rotating cylinder-shaped part called a brake drum.

The term drum brake usually means a brake in which shoes press on the inner surface of the drum.

A brake combining a leading and trailing (secondary) shoe in a single drum is called a simplex, or leading/trailing type.

This type of brake is equally effective for forward and reverse braking and offers stable braking force.

In general, it is used most often as a rear brake in passenger vehicles.

When the brake is applied, the shoe moves and presses the lining against the inside of the drum.

The friction between lining and drum provides the braking effort. Energy is dissipated as heat.

Modern cars have disc brakes all round, or discs at the front and drums at the rear.

Listen to the Text: