Under the Hood

Listen, repeat, memorize!

Camshaft

The camshaft is a rotating shaft (or shafts) in an engine that activates the intake and exhaust valves for each cylinder.

As the shaft turns, cams along its length press down on the spring-loaded valves in synchronicity with the motion of the pistons and firing of the spark plugs.

An engine may have one camshaft to operate all the valves or separate shafts for intake and exhaust valves.

Overhead-camshaft engines have separate shafts for each cylinder bank, so a V-configuration engine like a V-6 or V-8 can have two or four camshafts.

The camshaft uses lobes (called cams) that push against the valves to open them as the camshaft rotates; springs on the valves return them to their closed position.

This is a critical job, and can have a great impact on an engine’s performance at different speeds.

Driven by the crankshaft, the camshaft has multiple elliptical lobes (cams), one for each intake and exhaust valve contained in the engine.

As the camshaft rotates, the lobes regulate the opening and closing of the valves.- Listen to the Text:

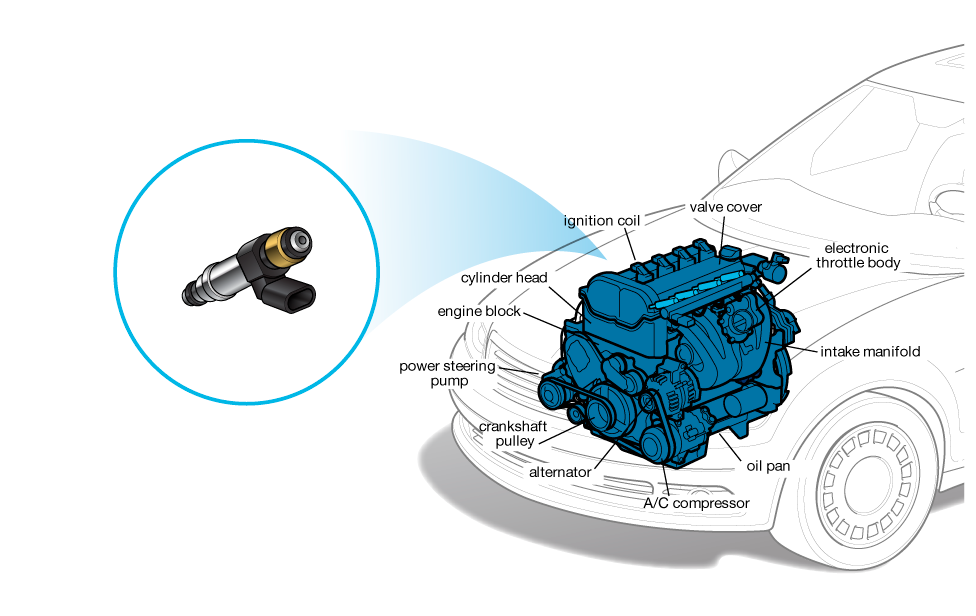

Fuel Injector

Listen, repeat, memorize!

Fuel injection is the introduction of fuel in an internal combustion engine, most commonly automotive engines, by the means of an injector.

All diesel engines use fuel injection by design.

Petrol engines can use gasoline direct injection, where the fuel is directly delivered into the combustion chamber, or indirect injection where the fuel is mixed with air before the intake stroke.

On petrol engines, fuel injection replaced carburetors from the 1980s onward.

The primary difference between carburetors and fuel injection is that fuel injection atomizes the fuel through a small nozzle under high pressure, while a carburetor relies on suction created by intake air accelerated through a Venturi tube to draw the fuel into the airstream.

The tip of the fuel-system spear, fuel injectors incorporate an electronically controlled valve and a nozzle that sprays fuel into each of an engine’s intake ports, or directly into its cylinders.

Now the norm for more than 20 years, fuel injection has practically eliminated the complications of cold starts, engine flooding and altitude sensitivity.

Fuel injector failure might appear as rough engine performance and/or hesitation, likely accompanied by the check engine light.

Fuel leaks are another possible, and dangerous, sign of failure, often at the seal where the injector meets the engine.

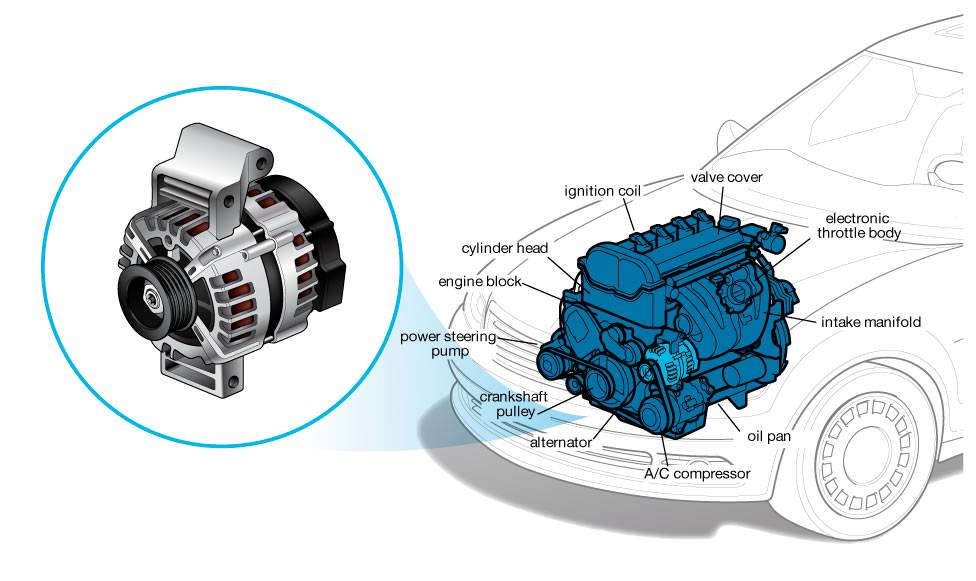

Listen to the Text:- Alternator

Listen, repeat, memorize!

Alternators are used in modern automobiles to charge the battery and to power the electrical system when its engine is running.

Until the 1960s, automobiles used DC dynamo generators with commutators.

With the availability of affordable silicon diode rectifiers, alternators were used instead.

This was encouraged by the increasing electrical power required for cars in this period, with increasing loads from larger headlamps, electric wipers, heated rear windows and other accessories.

The alternator is a generator that produces electricity to power the car’s ignition system, lights and accessories.

The engine drives the alternator by means of a belt, either with a dedicated belt or a belt shared with other pulley-driven components.

An alternator will stop immediately if its drive belt breaks, but alternators can also fail over time and with use, requiring replacement.

Failing alternators can result in repeatedly drained batteries, dimming headlights and localized noise.

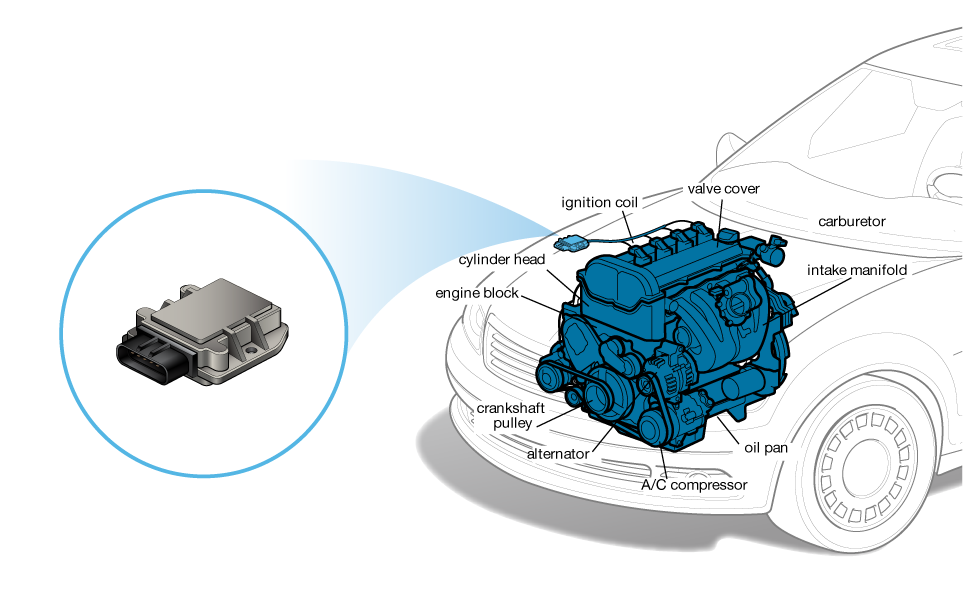

Listen to the Text:- Ignition System

Listen, repeat, memorize!

An ignition system generates a spark or heats an electrode to a high temperature to ignite a fuel-air mixture in spark ignition internal combustion engines oil-fired and gas-fired boilers, rocket engines, etc.

The widest application for spark ignition internal combustion engines is in petrol (gasoline) road vehicles: cars (autos), four-by-fours (SUVs), motorcycles, pickups, vans, trucks, and buses.

Compression ignition Diesel engines ignite the fuel-air mixture by the heat of compression and do not need a spark.

They usually have glowplugs that preheat the combustion chamber to allow starting in cold weather.

Other engines may use a flame, or a heated tube, for ignition. While this was common for very early engines it is now rare.

The ignition system’s job is to ignite the air-fuel mixture in a gasoline engine.

In addition to the spark plugs that spark in the combustion chambers, the ignition system consists of an ignition coil, which converts battery voltage to higher voltage, and the spark plug wires that join these components.

Advancements have greatly reduced the need for ignition system service.

Where distributor caps and rotors once needed replacement, electronic ignitions typically keep on firing.

In new vehicles, spark-plug replacement intervals are often around 100,000 miles.

Listen to the Text: